The furnace conductor & potter professions

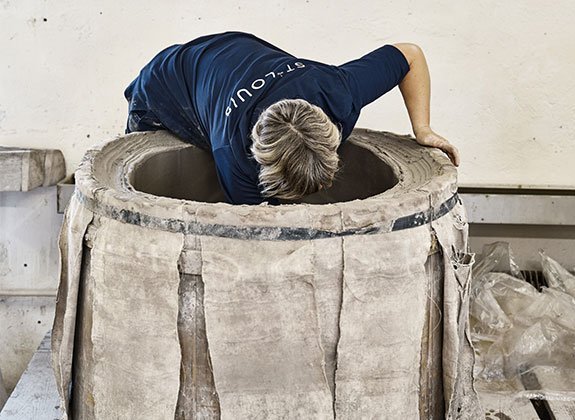

Changing these refractory earthenware pots is the most technical and spectacular operation in the tiseur's craft; a critical technique to prevent impurities from cracking clay. Still handmade by Saint-Louis potters and dried for months, the clay pot ensures optimum fusion and perfect crystal color.

Do you know what being a potter involves?

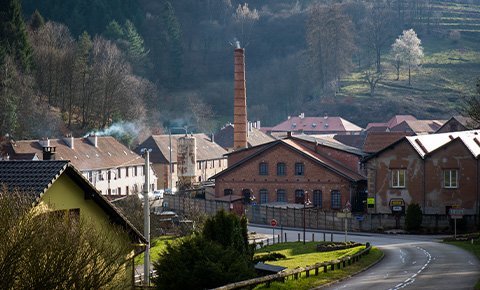

Six o’clock in the morning. Within the walls of the Manufacture, two crucible-makers rhythmically knead the clay in a wooden hall devoted to producing, drying and storing the crucibles. Some twenty receptacles are lined up, hooded like monks attending vespers. For four hundred years, Saint-Louis has crafted its own crucibles. This rare and little-known savoir-faire is brought to life by Christine and Guy. Crucibles are one of the Manufacture’s secrets, an unspoken secret, a secret of the earth. They are as matte and monochromatic as Saint-Louis crystal is ethereal and multicoloured. The crucible hall is as damp and silent as the glassmakers’ hall is burning and bustling. And yet they face one another. Glassmakers come to the hall to collect the crucibles, horseshoes, goggles and other accessories that allow them to melt crystal at 1,300°C, contained by the might of the fire clay.

Know-howSaint-Louis

DISCOVER MORE