KNOW-HOW

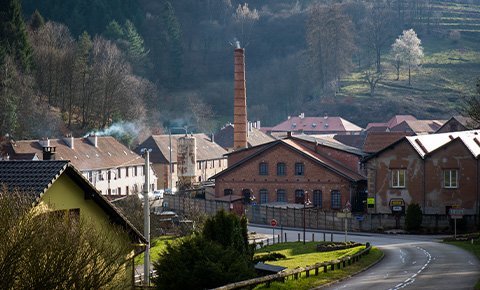

The Manufacture

The hotWorkshop

At Saint-Louis, the hot workshop - when and whereby crystal glass is produced under high temperature - is the essence of the central hall, the beating heart of the workshop.

-

Step 01Fuse

It is in the heart of the continuous casting furnace that the melting of the crystal takes place at 1450 ° C in the form of a malleable incandescent lava free of all its impurities before being deposited in the sampling zones.

-

Step 02Collect

It is in these “collecting bays”, maintained at a constant temperature of 1200 ° C, that the glassmakers “pick up” at the end of their cane the crystal quantity necessary for the production of a unique piece, from the glass to the chandelier branch

-

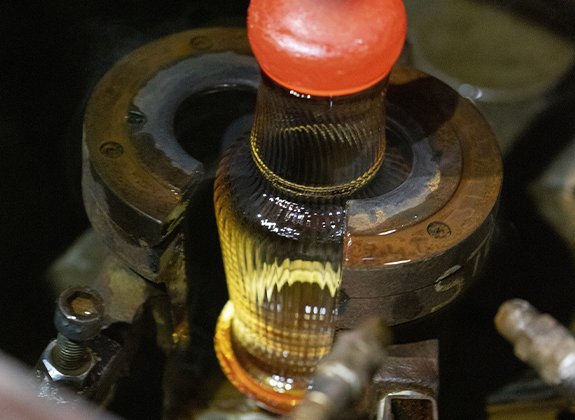

Step 03Shape

The glassblowers are like ogres with the finesse of embroiderers. They are men with lung power, whose breath kisses and kindles the orange mass at the end of the blowpipe; then they place the molten glass in a mould of beech wood or steel, where, in a fury of flames and steam at 900°C, the initial form of the object, the parison, is pressed.

The Manufacture

The cold Workshop

ATo the instinctive breath and blow of the hot workshop, the meticulous cold workshop imparts a studious atmosphere to Saint-Louis.

-

Step 01 Cut

What type of cuts are we referring to? In pearl, olive, almond, bevel ... From the star-shaped cut to the iconic diamond cut, the work of the master cutter is above all that of a decorator. The “cold” is a craft of art and excellence: gestures are refined, constantly perfected - from 30 to 35 interventions are necessary for a glass engraved and decorated with fine 24-carat gold.

-

Step 02 Decorate

The piece is engraved with acid and decorated with gold or platinum by brush and hand only. The piece with gold or platinum is then annealed at 500 degrees.

-

Step 03 Choose

A demanding control is present throughout the manufacturing process. The pieces are examined is chosen, under the watchful eye of our “selectors”.

-

Step 04 Sign

After this meticulous choice, Saint-Louis can affix its signature. The pieces are finally ready to leave the manufacture, carefully packed in a box wearing the colours of the Maison, the Saint-Louis blue.

Manufacture

The haute-couture of crystal

Two months is all the time it took the Saint-Louis craftsmen to make one of the largest chandeliers in the world.

-

Step 01Corps de ballet

It is in the great hall, the hot-glass workshop, that the expert waltz of the glassmakers around the incandescent susbtance begins. They glide around like a corps de ballet, with confident and well-rehearsed movements that have been passed down through the ages, each time renewing the wonder that is crystal. It is a fierce battle between heavy matter and time, which is short because crystal hardens at room temperature.

-

Step 02Trial by fire

Flushed by the heat, the most powerful of the glass-blowers plunges a heavy iron rod into the incandescent mass, gathers the glowing molten substance into the ball and then carries it to the master glass-maker. Standing, he shapes it with a wooden board. Sparks fly.

-

Step 03Swirl

Nearby, another glassmaker holds the blowpipe, turns it, and twists, hollows out and stretches the thich mass into a fine coil. Together the workmen slide the red-hot crystal into an S-shaped mould, where it hardens instantaneously. That's it! The last branch of the largest chandelier ever to come out of these workshops has come to life.

-

step 04A steady hand

Having endured the trial by fire, the piece of crystal is separated from the craftsman's rod with a drop of water. It may now leave the great hall for the cold workshop. The craftsman can proceed to cutting and decorating the crystal. Under his expert fingers, the rough outline of the patterne to be cut takes shape. A steady hand and a perfect eye are required!

-

Step 05Assembly, disassembly, reassembly...

In the chandelier workshop, the test assembly of the chandelier has already begun. The construction plan is complex. Then, gradually, the cut crsytal branches, bowls, cups, clothe the metal skeleton. Standing at the top of the ladder, the fitter screws on the light bulbs and positions the hurricanes on the crystal arms. Light and gold flash in the facets of each of the 3 000 pieces of crystal that make up the chandelier. Turn on the lights!